Overview products < Manifold units < Full system rotary manifold

Rotary dry break manifold

This manifold unit has been applied for 25 years now. It can concentrate or distribute a

maximum of 18 lines to two lines. This manifold guarantees leakage-free connections

during and after coupling, regardless of pressure and flow direction. After loosening

a connection there is no more contact between the product areas, a complete product

separation is given. Moreover, on opening or disconnecting of the lines there is no

formation of bubbles. This is a big advantage for the operation of mass meters. As an

option the manifold can also open against locked-in pressure (up to nominal pressure).

- Complete separation of different product lines

- Possibility of coupling and decoupling under high pressure and independent of flow direction

- Minimal flow resistance thanks to favourable shape and maximum utilisation of cross section

- Automatic or manual operation

- Almost zero product loss during decoupling. Therefore this manifold is a very safe and environment-friendly multi line coupling.

- The pipeline connection closes automatically on loss of control air

- No need for additional isolation valves in manifold valve's area

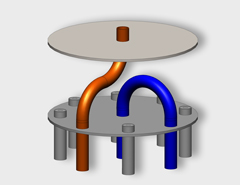

The full system rotary manifolds are based on one or two U-arms which turn centrally above

each other. These U-arms are connected to pipelines with are arranged radially.

The disconnecting points of the single pipeline systems are equipped with dry-break

couplings. These facilitate a safe product separation and there are almost no residuals.

The full system rotary manifolds are based on one or two U-arms which turn centrally above

each other. These U-arms are connected to pipelines with are arranged radially.

The disconnecting points of the single pipeline systems are equipped with dry-break

couplings. These facilitate a safe product separation and there are almost no residuals.

This is a manual full system rotary manifold 1 to 14 with U-arm. Opening,

closing as well as interlocking are effected pneumatically. Here: Size DN 80

A fully automated rotary manifold 1 to 10 in size DN 25 with S-arm.

Here: Mounting position overhead

The connection of male and female coupling of the fully automated rotary manifold (see above) is done

via a pneumatically driven half ring.

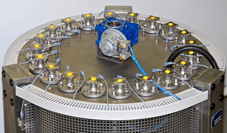

Fully automated rotary manifold 1 to 20 in size DN 25 with S-arm. Here: Mounting position overhead

View from above – fully automated rotary manifolds 1 to 20 in size DN 25 with incoming pipe connection.

The rotary actuator is installed in the centre.